No. 1/223-1, Kaliamman Koil Main Road, Karapakkam, OMR, Chennai – 600 097

-

Call Us

+91 8667388859

-

24/7 Support

-

Email Id

jayamservices@gmail.com

Jayam Engineering Services

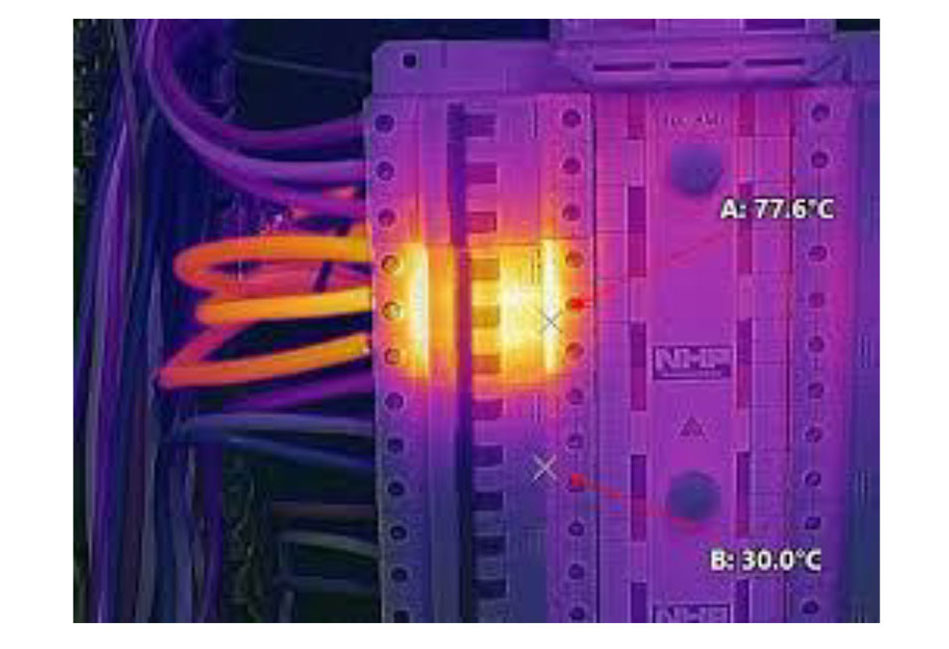

THERMOGRAPHY STUDY

It is a non-contact technique which is used to detect the fault of the electrical equipments. Every object emits thermal energy which is invisible. So, we use thermal camera to capture the thermal energy of electrical equipments to the analyzation of faults. Infrared scanning detects abnormal heat signatures, indicating loose connections, overloaded circuits or fault equipments.

Thermal imaging cameras help in quick and accurate scanning of the entire surface of an electrical equipment or machinery to visualize the temperature differences in the form of thermal images. In in manufacturing industries, thermography helps the maintenance experts in detecting problem areas & hot spots for preventing production downtime and major electrical fires.

Thermography in utilities helps to detect problems during power generation, distribution and transformation.

BENEFITS OF THERMOGRAPHY TEST:

Incididunt ut laboret dolore magna aliqua. At enim trud exercitation dolor ullamco laboris nisut aliquip aute irure dolor in reprehenderit.

- It keeps user out of danger while scanning live electrical components.

- Predictive maintenance – thermography helps identify potential issues before they become major problems.

- early detection of thermal anomalies minimizes unexpected shutdowns.

- Increased safety – identifies overheating components, reducing risk of electrical fires.

- Energy efficiency – detect energy loses due to inefficient connections or components.

- Extended equipment life – prevents premature wear and tear on electrical equipments.

- Cost savings – avoids costly repairs and replacements.

- Real time monitoring – enables instant assessment of electrical systems

- Enhanced reliability – ensures continuous operation of critical electrical systems.

- Simplified trouble shooting – pinpoint exact locations of thermal issues

- Data- driven decision making – provides quantitative thermal data for informed maintenance decisions.

Jayam Engineering Services

List of Testing Kits and Equipment’s

Primary Injection Kit.

Secondary Injection Kit (Single phase & 3 Phase)

Contact Resistance Meter - CRM 100B make Scope.

Time Interval Meter – SCOT MXP make Scope.

SF6 Gas Leakage Detector make DILO 3-033-R002.

Transformer oil filtration machine up to 6KL

SF6 Gas Cylinder With filling kit.

Digital Insulation Resistance Tester (250V to 5000V Dc) .

Analog Insulation Resistance Tester (500V,1000V,5000V) .

Earth Resistance Tester (Analog and Digital).

Digital Multi Meter (fluke make).

Phase Sequence Indicator.

Digital Clamp Meter (kyoritsu make).

Digital Leakage Meter (kyoritsu make).

High voltage Test Kit (0- 80KV AC/DC).

Transformer winding Resistance meter (Scope Make).

Transformer Testing Kit.

Vacuum pump

Micro Ohm Meter.

L&T Universal Test Kit.

ACB Release Test Kit (ABB & Siemens).

Thermal Scanner (Fluke Make).

Power Quality Analyser.

Cable Fault Locator kit