No. 1/223-1, Kaliamman Koil Main Road, Karapakkam, OMR, Chennai – 600 097

No. 1/223-1, Kaliamman Koil Main Road, Karapakkam, OMR, Chennai – 600 097

Call Us

24/7 Support

Email Id

AN ISO 9001 2015 Certified Company Electrical Engineers and ‘A’ Grade Contractor Engineering Services

We would like to give self-introduction by presenting our company profile to you for your reference

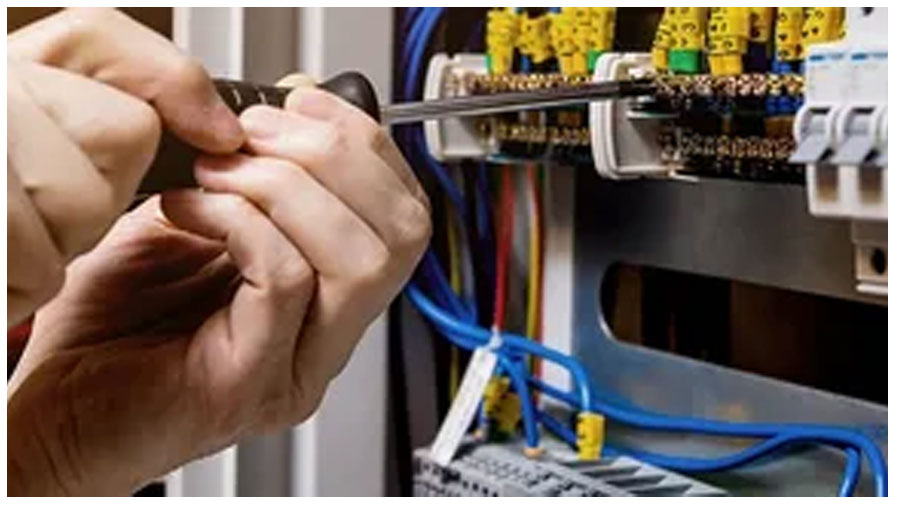

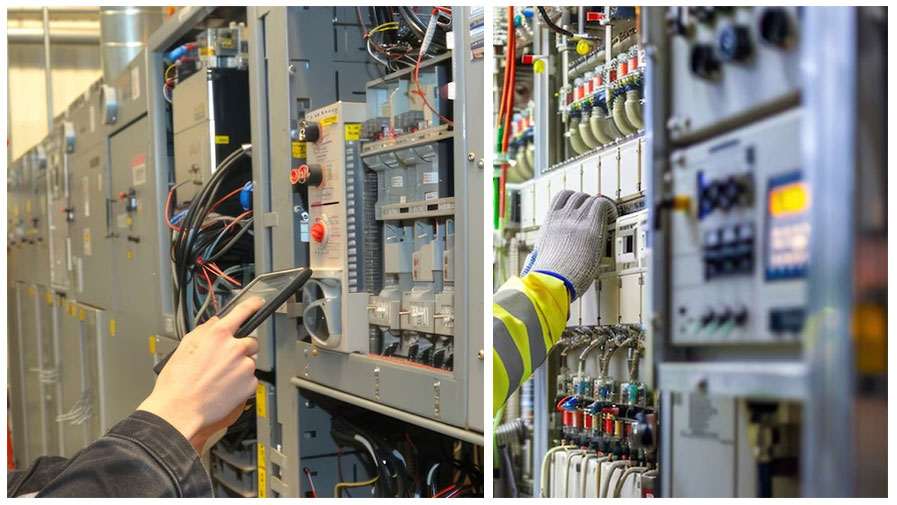

We are an and professional electrical contracting company, has executed several L.V/M.V and H.V services for a wide spectrum of industries. Our major classification of services are preventive maintenance, testing, trouble shooting and spares supplying of L.V/M.V and H.V circuit breakers, transformers.

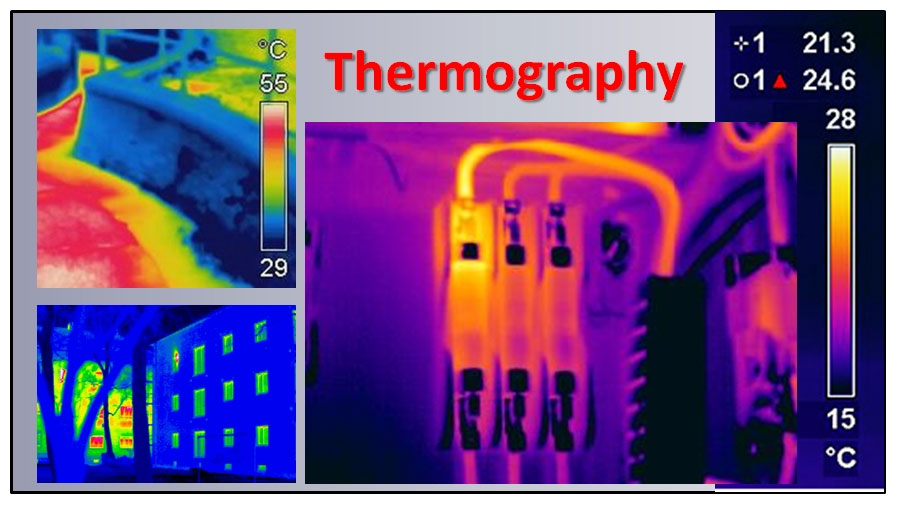

It is a non-contact technique which is used to detect the fault of the electrical equipments. Every object emits thermal energy which is invisible.

Cable fault location involves identifying the exact location of faults, such as cable shorts, grounds or open circuits in underground or sub merged cables.

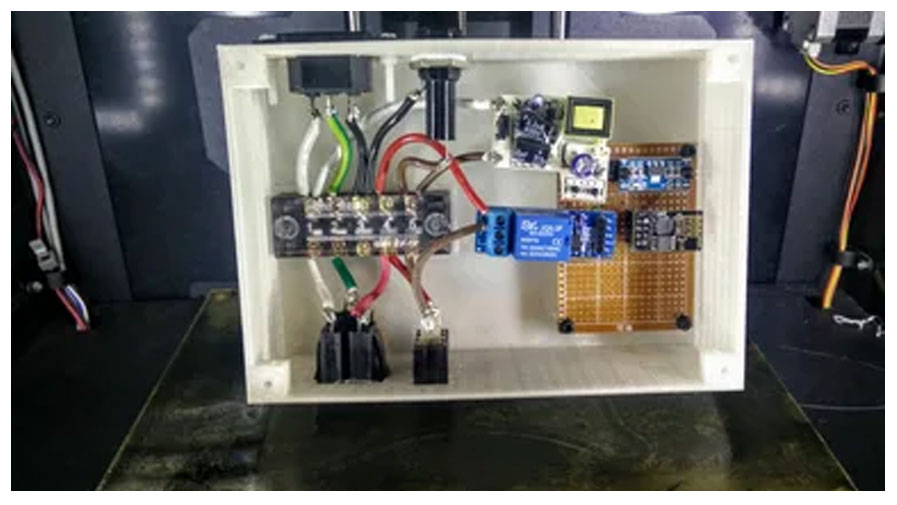

Technology gets evolve day by day and all the systems have many upgrades in its design, operation, usage and etc.

HT and LT panel services are important to ensure the safety, reliability and performance of electrical systems.

Transformer oil filtration is the cutting-edge technology used to enhance oil purification and re use.

Transformer plays a major role in power generation, transformation, distribution and utilization of electrical systems. So, it should be regularly maintained yearly once is most important.

Annual Maintenance contract (AMC) is a type of Service Agreement that provides ongoing maintenance and support for a specific equipment or asset.

Power quality is one of the major critical topics in industrial facilities as well as one of the major untapped zones of expense reduction and economic gain in today’s businesses.

Proper preventative maintenance performed by a NETA-certified technician can extend the working life of your electrical infrastructure and reduce the likelihood of expensive repairs.

An Arc Flash Assessment / Analysis is a study of the facility’s power system to determine the incident energy available at specific electrical devices that employees would be exposed to while “interacting with” the electrical equipment at the facility.

Protection relays operate under the assumption that they will function flawlessly when called upon to respond to a fault.

a) Mechanical servicing of VCB mechanism like manual close, trip and electrical close trip .Visual inspection of all parts. Servicing like cleaning, lubrication. If Spares required during services (All breaker makes), to be supply and fix.

b) Spring charging(manual or electrical motor)

c) Checking of control wirings.

d) Overall insulation value (megger value) test.

a) Circuit Breaker (VCB closed and open condition), CT/PT Insulation Resistance Measurement test. Tests have been conducted using a 5KVA/230V DG set.(Megger)

b) Operational Checks like draw-out mechanism, spring charging, Interlock Functions, operation of Auxillary switch/V releases/T release, operation of Earth switch.

c) Over Current Earth Fault Relay Primary Injection Testing.(at relay services settings)

d) Primary Injection Test of Potential core and Metering core using Primary injection kit and relevant instruments.

Upgrading technology with cost effective solutions The concept of ‘Retrofitting’ does not call for replacing the entire switchgear. Retrofitting does not require:

A) Modification in foundation.

B) Change in the power cable route.

C) Change in control cable route.

D)Shutdown

Example:

a) Frequency and level of maintenance are high.

b) limited operational and short-circuit life.

c) Vulnerable to fire hazards associated with oil.

Advance to new technology, viz. vacuum, with its superior dielectric and arc interruption properties.

‘RETROFITTING’ old MOCB switchgear with VCB is the cost effective, which will improve the life and reliability of switchgear without going for large investment.

CASETTE-TYPE DRAW-OUT UNIT is offered with complete safety interlocks,shutter,contact shrouds ets.

Every four months mandatory visit is made by JES to examine every breaker.

In addition to that emergency call based visit will be made by JES.

All make like Siemens,ABB,Areva,L&T,CGL,BHEL,Easun,S&S,Jyoti,Biecco lawrie,SYSTEM CONTROL and etc; spares and technical experts available with us.so we can provide best service.

Our service charges competitively less. Our motto is the best service.

Primary Injection Kit.

Secondary Injection Kit (Single phase & 3 Phase)

Contact Resistance Meter - CRM 100B make Scope.

Time Interval Meter – SCOT MXP make Scope.

SF6 Gas Leakage Detector make DILO 3-033-R002.

Transformer oil filtration machine up to 6KL

SF6 Gas Cylinder With filling kit.

Digital Insulation Resistance Tester (250V to 5000V Dc) .

Analog Insulation Resistance Tester (500V,1000V,5000V) .

Earth Resistance Tester (Analog and Digital).

Digital Multi Meter (fluke make).

Phase Sequence Indicator.

Digital Clamp Meter (kyoritsu make).

Digital Leakage Meter (kyoritsu make).

High voltage Test Kit (0- 80KV AC/DC).

Transformer winding Resistance meter (Scope Make).

Transformer Testing Kit.

Vacuum pump

Micro Ohm Meter.

L&T Universal Test Kit.

ACB Release Test Kit (ABB & Siemens).

Thermal Scanner (Fluke Make).

Power Quality Analyser.

Cable Fault Locator kit